In the world of precision engineering, having the right tools can make all the difference. Whether you’re crafting intricate components for aerospace applications or fine-tuning parts for medical devices, the accuracy and reliability of your machining tools are paramount. In this post, we’ll explore some of the top high-precision machining tools of 2024, evaluating their features, performance, and overall value.

Table of Contents

1. Makino V90S Vertical Machining Center

Features:

- High Precision: The V90S boasts ultra-high precision, thanks to its advanced spindle technology and rigid construction.

- Speed: With rapid traverse rates and high-speed spindle options, it’s designed for high productivity.

- Versatility: Suitable for a wide range of applications, from mold making to high-performance part manufacturing.

Performance:

- Accuracy: Achieves sub-micron level precision, ideal for demanding applications.

- Stability: Exceptional thermal stability ensures consistent performance.

- User-Friendly: Intuitive control systems and easy maintenance.

Pros:

- Exceptional precision and stability

- High productivity and versatility

- User-friendly interface

Cons:

- High initial investment

- Requires significant floor space

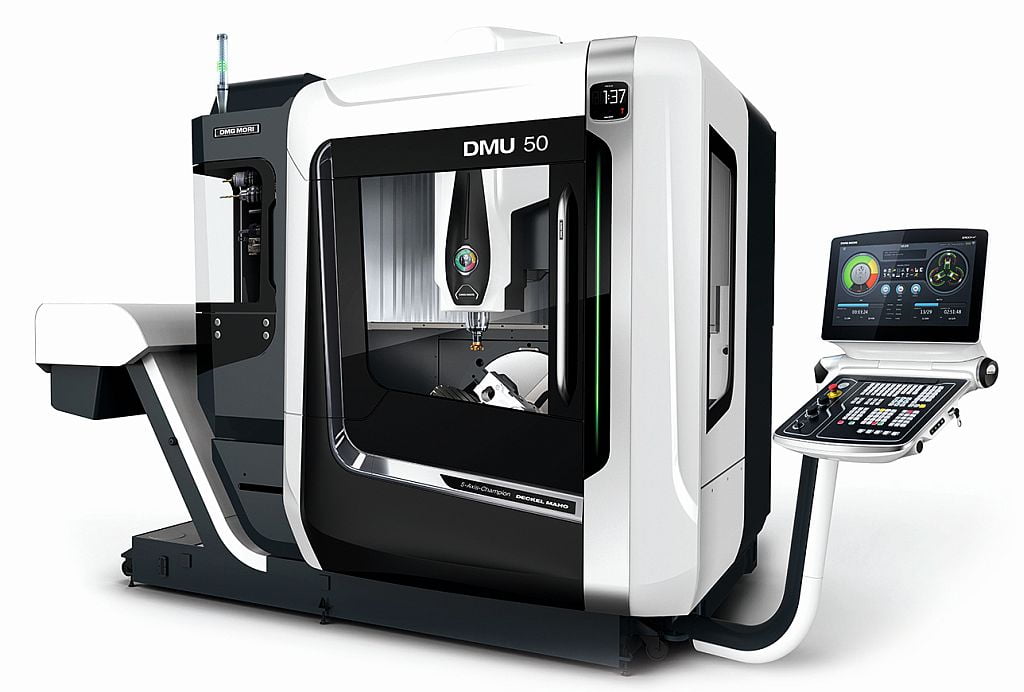

2. DMG MORI DMU 50 3rd Generation

Features:

- 5-Axis Machining: Offers unparalleled flexibility with simultaneous 5-axis machining capabilities.

- Compact Design: Space-saving design without compromising on performance.

- Advanced Controls: Equipped with CELOS and Siemens control systems for ease of use.

Performance:

- Precision: Maintains high accuracy even in complex geometries.

- Efficiency: High-speed machining reduces cycle times.

- Reliability: Built with robust components to ensure long-term durability.

Pros:

- Compact yet powerful

- Excellent 5-axis capabilities

- Advanced control systems

Cons:

- Limited working envelope compared to larger machines

- Learning curve for advanced controls

3. HAAS UMC-750

Features:

- Cost-Effective: Combines high performance with affordability.

- Versatility: 5-axis universal machining center suitable for various applications.

- Robust Construction: Built to withstand rigorous machining tasks.

Performance:

- Accuracy: Delivers precise machining for both small and large components.

- Speed: Efficient machining with minimal setup time.

- Ease of Use: User-friendly interface simplifies complex operations.

Pros:

- Affordable for a high-precision machine

- Versatile applications

- Easy to operate

Cons:

- Not as fast as some high-end models

- Requires regular maintenance

4. Okuma MU-8000V Laser EX

Features:

- Hybrid Machining: Combines additive and subtractive manufacturing in one machine.

- Advanced Laser Technology: Enables complex part production with high precision.

- 5-Axis Machining: Offers flexibility and precision for intricate components.

Performance:

- Innovation: Excels in producing complex geometries with minimal waste.

- Precision: Maintains high accuracy in both additive and subtractive processes.

- Efficiency: Reduces lead times and material costs.

Pros:

- Innovative hybrid capabilities

- High precision and efficiency

- Reduces material waste

Cons:

- High initial cost

- Requires specialized training

5. Brother SPEEDIO R650X1

Features:

- High-Speed Machining: Offers rapid machining capabilities with minimal setup times.

- Compact Design: Ideal for smaller workshop spaces without sacrificing performance.

- Eco-Friendly: Energy-efficient design reduces operational costs and environmental impact.

Performance:

- Precision: Delivers high-accuracy machining, suitable for small to medium-sized components.

- Speed: Exceptional speed and efficiency, making it ideal for high-volume production.

- Reliability: Known for its durability and low maintenance requirements.

Pros:

- High-speed and efficient

- Compact and energy-efficient design

- Reliable and durable

Cons:

- Smaller working envelope compared to larger machines

- May not be suitable for very large components

Conclusion

Choosing the right high-precision machining tool depends on your specific needs and budget. The Makino V90S stands out for its exceptional precision and stability, making it ideal for the most demanding applications. The DMG MORI DMU 50 3rd Generation offers advanced 5-axis capabilities in a compact design, while the HAAS UMC-750 provides a cost-effective solution without compromising on performance. For those looking to innovate, the Okuma MU-8000V Laser EX offers groundbreaking hybrid machining capabilities. Meanwhile, the Brother SPEEDIO R650X1 offers high-speed machining in a compact and eco-friendly design, perfect for smaller workshops and high-volume production.

Investing in high-precision machining tools can significantly enhance your manufacturing capabilities, ensuring consistent quality and efficiency. Evaluate your requirements carefully and choose a tool that aligns with your production goals.